-

Peptide Synthesis Filtration Jacketed Glass Reactor for Crystallisation and Solid-Liquid Separation

-

-

Reaction and Filtration in one Reaction Vessel

- Integrated PTFE Filtration for Crystallisation or Peptide Synthesis

-

-

- PTFE Filtration without any Metal or other Pollution.

-

- Full-Jacket Thermal Layer. No Any Thermal Transfer Dead-Space.

-

- Thanks to Auxiliary Lifting-Arm for easy PTFE filtration module Installation.

-

- Ideal Design for crystallization, solid-liquid separation and polypeptide synthesis.

-

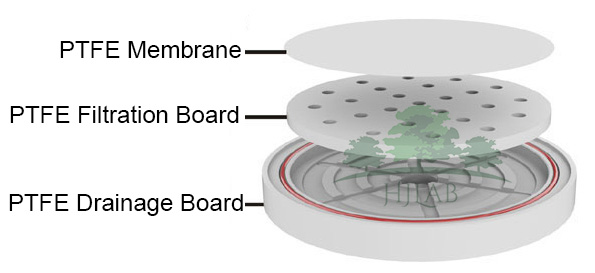

PTFE Filtration Module Structure

|

Structure Description as following: 1) PTFE Coated O-Ring |

|

-

General Specifications

|

Items |

Details |

|

Glass Materials |

High Borosilicate Glass 3.3 |

|

Wetted Parts |

Glass and PTFE |

|

Reaction Vessel Capacity |

5L, 10L, 20L, 30L, 50L, 80L, 100L, 150L, 200L Vertical Baffles inside of the vessel (Optional) |

|

Thermal Jacket |

Ring Baffles within the Thermal Jacket (5L, 10L, 20L, 30L) Full Jacket Design (5L, 10L, 20L, 30L) |

|

Filtration Area |

ID215 Flange: 346 cm² (5L, 10L, 20L, 30L, 50L) ID280 Flange: 615 cm² (30L, 50L, 80L, 100L) ID400 Flange: 1,256 cm² (50L, 80L, 100L, 150L, 200L) |

|

Filtration Micron |

Micron: 0.2μm to 200μm (depends on your materials) Filtration Materials: PTFE

Note: Not included by default |

|

Stirring Motor |

DC Brushless Motor, 50W, 100W, 150W AC Motor with Gear Reducer: 120W ~ 1500W Explosion-Proof Motor: 180W, 250W, 370W, 550W, 750W, 1500W

Stirring Range: 50 ~ 600 RPM

Realtime Display: Mixing Speed, Materials Temperature |

|

Mixing Sealing |

PTFE + Mechanical Optional: Magnetic coupling seal |

|

Condenser |

Cooling Coil Condenser |

|

Dropping Feeding Funnel |

Dropping Feeding Funnel with PTFE Metering Valve and Equalizing Arm |

|

Glass Lid |

Diameter: DN215, DN280, DN400 for your selection

7 Openings: 1) Dropping Feeding Funnel 2) Solid Materials Feeding 3) Stirrer 4) Liquid-Feeding 5) Temperature Probe 6) Condenser Reflux 7) Reserved (By default: Pressure Release) 8) Spray Cleaning or PH measurement (Optional) |

|

Stirring Impeller |

PTFE Anchor Type PTFE Pitched Paddle Type PTFE Frame Type |

|

Operating Temperature |

-90℃ to +230℃ |

|

ΔT - Thermal Shock Resistance |

90℃ (Double Wall) |

|

Operating Pressure |

Full Vacuum to Atmospheric Pressure |

|

Operating Jacket Pressure |

Up to +0.5 bar (0.05 MPa) |

|

Power Supply |

100V ~ 240V, 50Hz/60Hz |

-

Turnkey Package