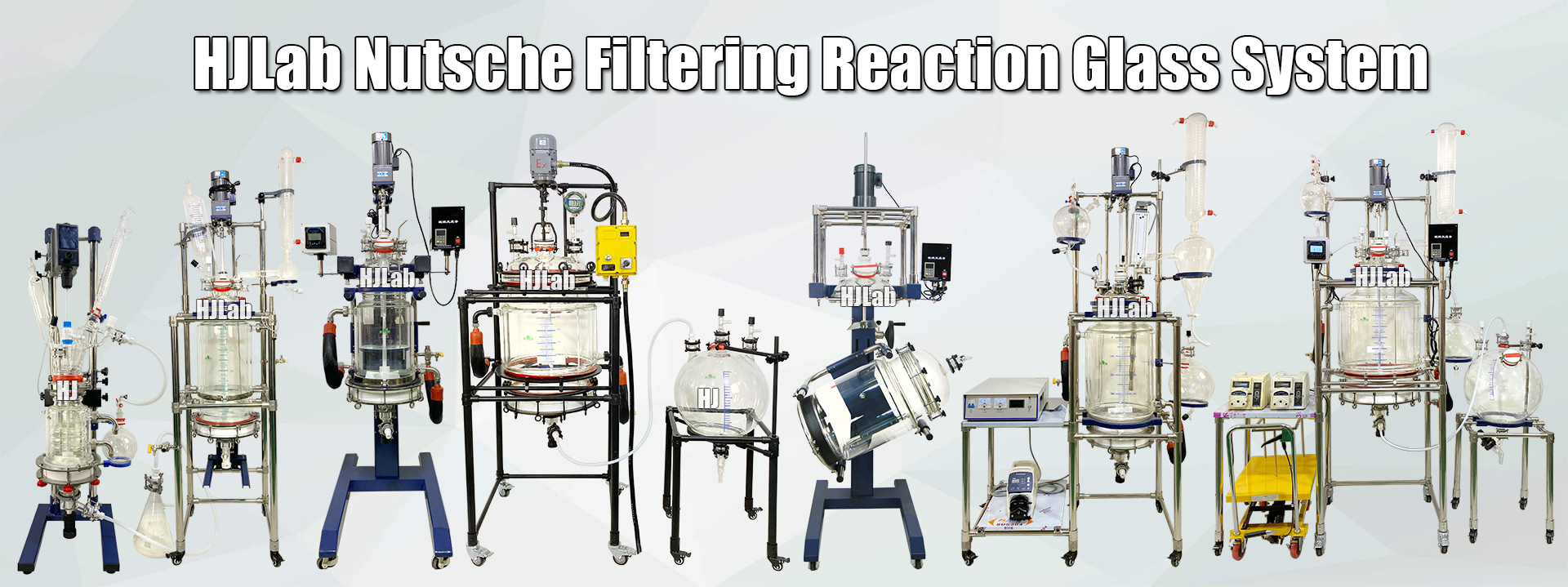

Glass reaction systems

HJLab glass reaction systems provide:

- Excellent performance

- Great user experience

- Best return on investment

The unique Ring Baffles in our jacketed glass reaction vessels offer exceptional control over process temperature. As a result, the chemical synthesis process is done quicker with high yield. Our optimised vessels allow efficient energy use. So, costs are saved over time. We offer glass reaction systems ranging from 300 mL to 300 L.

High performance & Great user experience

HJLab reaction systems provide high performance process conditions, resulting in higher yields and lower impurities.

HJLab reaction systems offer the great user experience, with a stress-free workflow that allows you to concentrate to your process.

-

High heat transfer

HJLab glass vessels achieve high heat transfer due to their capacity to rapidly heat or cool. Thermal energy is evenly distributed, which prevents uneven treatment of vessel contents.

-

- Optimized inner wall thickness

- Low jacket volume

- Ring Baffles

- High thermal shock resistance

-

High mass transfer

HJLab reaction vessels are optimized for high mass transfer, which is essential for reproduciblity and high yield.

-

- Vessel geometry similar to industrial glass-lined reactors

- Variety of impeller options to meet mass flow requirements

-

Consistency of proess scale-up

HJLab maintains consistency in scale-up by ensuring, where possible, similar vessel geometry across all vessel sizes.

-

- Maintenance of height to inner diameter ratio between 1:1 to 1:1.5

-

Quick set-up

HJLab glass reaction system do not require complex tools for installation. With the standard and premium options available, it is easy to switch vessels (in Lab-Scales) and to change the impeller if required (in All Reactors).

-

- Simple installation

- Lid accessories held securely while changing vessel or impeller

- Vessel, Motor or Lid lifting/tilting-assist mechanisms

- Flexiable heat transfer fluid hoses for use in tight spaces

- Vent and drain valves for quick and easy draining of heat transfer fluid

-

Easy maintenance

HJLab reactors are designed to be easily for cleaning, and feature easily replaceable parts in the event of a breakage.

-

- Removeable flush valve

- Easy vessel access in both benchtop and pilot plant scales

- In-place cleaning systems offered for large vessels

- Lifting and tilting design

- Grooveless flanges for pilot plant vessels

-

Easy configurable

HJLab glass reaction systems have a number of useful features for standard processes and process development. Standard configurations can also be modified to suit a specific process.

-

- Heating, cooling, stirring, reflux

- Ports for solids and liquids addition

- Vacuum distillation

- Inert reactions

- PH, Ultrasonic and Variety of special accessories for specific process requirements.